We provide efficient and cost effective assembly methods for any plastic assembly application.

Let us find the best solution for you, call 614.539.3222 for a quote.

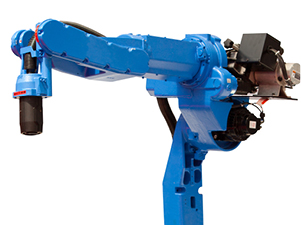

“We partner with ToolTex because of our proven history with them.

The application they create for us is pretty unique, only a handful of companies

in the U.S. do that work. ToolTex has the edge there.”

DAVE TOLLER, IAC