SSH2 - SimpleStake Handset 2

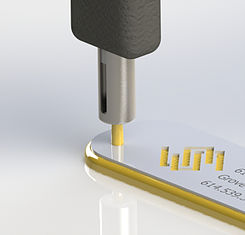

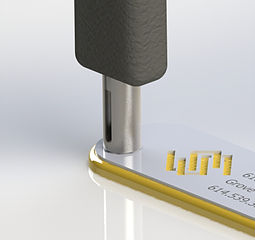

DURING THE STAKING PROCESS, A SOLID OR HOLLOW “BOSS,” OR TAB PROTRUDING THROUGH A MATED PART, IS HEATED TO A SOFTENING TEMPERATURE AND FORMED TO A HEAD THAT CAPTURES THE MATED PART.

Ideal for repairs or quick, small jobs, the SSHG2 delivers the same SimpleStake “heat on demand” performance in a handheld package. Sensitive electronics and painted surfaces are unaffected as the SimpleStake Handset 2 tool is clean and virtually string-free. The SSH2 promises to be cool to the touch at the end of each cycle, making it safe and easy to handle.

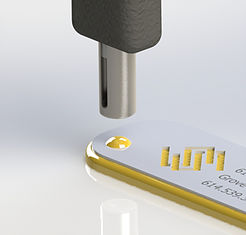

Quick ChangeTips

ToolTex makes changing or replacing tips in the SimpleStake Handset welder a simple 20-second quick-change operation. Simply remove the protective tip shell, unplug the existing tip assembly, plug in the new tip assembly, and replace the shell. Make your SimpleStake Handset more versatile and save time with the SimpleStake quick-change tip option.

New Handset Components

Inner 2-piece housing to hold harting connector pins, o-ring, and pneumatic connector

- quick access cover to replace O-ring if damaged.

- machined grooves to secure pins

New body and screw-on cap

- The body now has internal mounts for power leads and a pneumatic connector

- New body extended nose cover to house new tip potting

Accessories

- 2 extra O-rings with each handset

Upgrade an existing SimpleStake Handset

First gen handsets can be upgraded with the quick change option.