SPIN WELDING

For assemblies with circular mating surfaces, Spin Welding is a must. During the spin welding cycle, one part is spun against its fixed mating part to produce frictional heat at the joint interface.

This method prevents the need for conventional adhesives and mechanical fasteners to provide for a truly environmentally friendly process.

Is Spin Welding right for you application? Contact Us for more information.

Applications

Spin Welding is ideal for cylindrical or spherical assemblies, and can produce a bond stronger than the parent material with hermetic seals possible for most thermoplastics, including engineered resins. Filter and resin cartridges, twin-wall drinking cups and spools are just a few of the applications well suited to Spin Welding, but the process has wide ranging capabilities.

Precision

Along with traditional pneumatic configurations, ToolTex manufactures servo-driven spin welders that ensure the mating parts are aligned to +/- 1 degree and to just a few thousandths of an inch of desired closure dimension. This may be critical if the mating part features, such as ports or dial indications, must be in precise relationship after assembly.

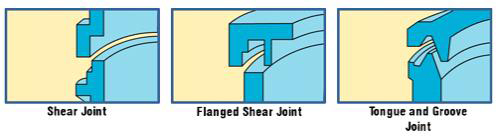

Joint Design & Tooling

For over 25 years, ToolTex has designed and built spin welders and unique tooling for parts ranging from 10mm to greater than 12” in diameter. You need not guess about joint design, torque requirements, tooling configuration, or weld parameters that best suit the application. We will work with you to understand the requirements of the assembly and advise you on the most efficient and cost effective method to achieve those goals.

Processing

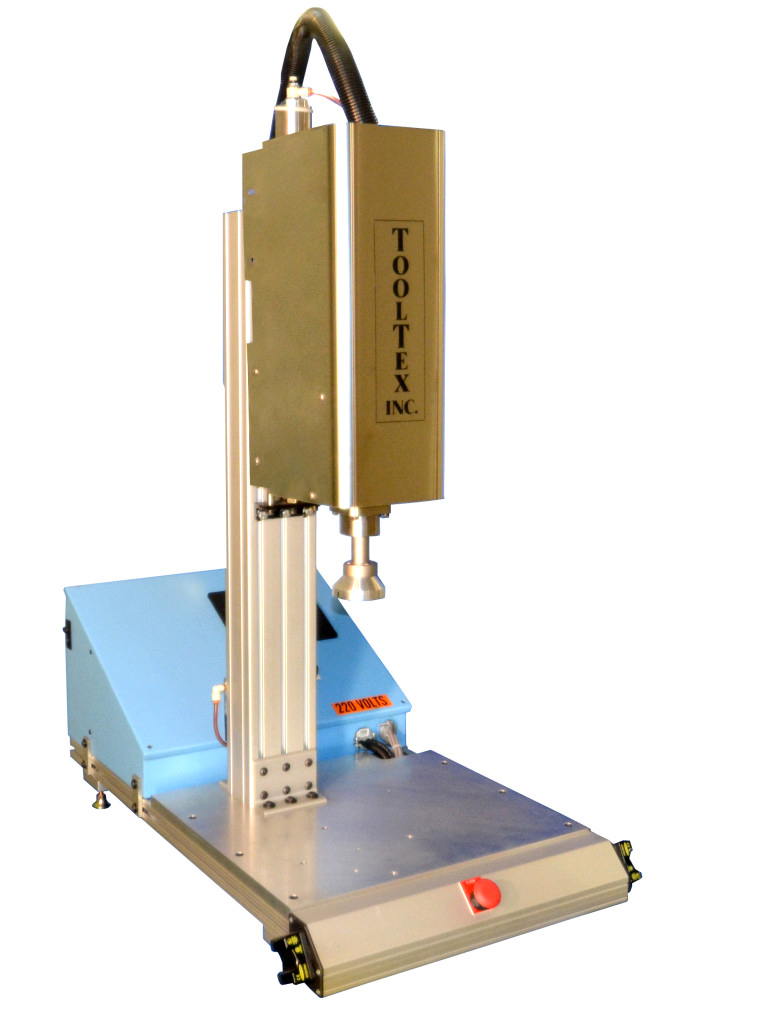

Spin welders range from compact tabletop units with dual anti-tie-down palm button actuation to fully automated systems that only require the operator maintain sufficient parts in the hopper/feeder. ToolTex designs and fabricates spin welders ideally suited to your requirements for parts per hour, strength, finished dimensions, orientation and cosmetic considerations.

High Torque 1kW Vertical Spin Welder

750W Horizontal Spin Welder

High Torque 3kW Vertical Spin Welder