INDUCTIVE INSERTION PRESS

Inductive insertion is a process by which threaded metal inserts are rapidly heated through the use of induction and then inserted into plastic parts for a strong and lasting bond.

During the process, inserts are loaded by the operator or automated feeder bowl, moved into the induction coil, heated, and then driven into the plastic part – often with no flash visible.

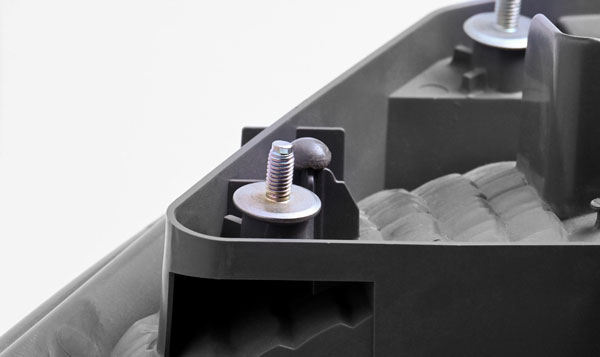

During the insertion process, inserts need a secure and precise method for placement, ensuring optimal bonding with the main material.

ToolTex’s Inductive Insertion Press is a solution that stands apart from the dated ultrasonic or heated probe insertion methodologies dating back to the 1950s. This system addresses conventional methods' specific challenges and paves the way for faster, more efficient, and damage-free insertions - especially crucial for industries demanding the utmost accuracy.

- Medical devices

- Electronics

- Automotive

- Aerospace

- Precision manufacturing

Unlike traditional insertion techniques that rely on constant heat or high-frequency vibrations, ToolTex’s Inductive Insertion Press combines the power of vacuum and rapid induction heating. Once set up, the press requires minimal oversight, presenting an effortless operation with consistent results.

Benefits

- Quiet and Clean: Inductive insertion eliminates noisy operations and provides a dust-free workflow.

- Swift Processing: Experience insertion speeds five times higher than heated probe insertion systems.

- Precision at its Best: Ensure each insertion is as accurate as the last one.

- User-Friendly: Designed with a user-centric approach, it's easy to operate and maintain.

- Cost-Effective: Get more done at a lower operating cost.

Features

- Fully programmable insertion cycle: Store up to 20 jobs in PLC/HMI for quick access

- Versatile Insert Capabilities: Supports insert sizes from #6 to 3/8” (M2.5 to M8)

- Replaceable Vacuum Insert Holding Tip: Doubles as a part presence sensor. Features reversible vacuum at the tip for cooling the placed insert.

- Dual anti-tie-down cycle start with Emergency stop: Automatic E-stop upon unintended induction coil impact

- Adjustable opening: From the base plate to max coil height

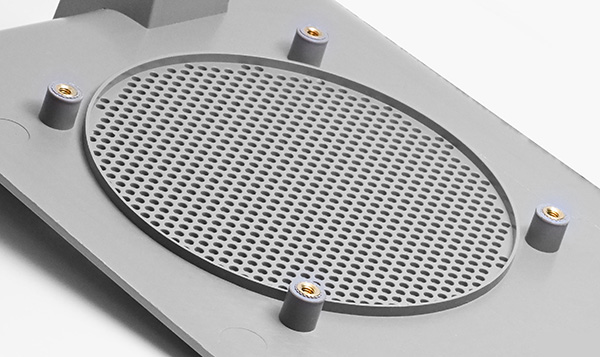

- X” x Y” tooling plate: With hardened bushings for pinnable nesting fixtures to ensure positive alignment with quarter-turn lock-down for quick-change tooling

- Enclosed air-cooled induction coil

- Maximum thruster speed of 200mm/S

Accessories

- Nested part presence sensing option (e.g., through beam, reflective sensor, or inductive proximity sensor)

- Pinnable fixturing for positive location

- Variety of insertion tip sizes

Specifications |

|

|---|---|

| Model | Inductive Insertion Press |

| Insert Force | 125 lbs. |

| Mounting Area | 12” D, 14” W |

| Stroke | 15.5” |

| Throat | 3-5/16” |

| Electrical | 110V, 15A |

| Overall Dimensions | 23” D, 18.75W, 36.5H |

| Air Consumption | 4 CFM |

| Approx. Shipping Weight | 115 lbs. |