HOT PLATE WELDING

In the hot plate welding process, parts are brought into contact, or nearly in contact, with a heated platen or focused infrared heat source to encourage flow at the joint.

In the hot plate welding process, parts are brought into contact, or nearly in contact, with a heated platen or focused infrared heat source to encourage flow at the joint. The platen is quickly retracted and the heated parts are brought into contact with each other at the interface under pressure until the material is sufficiently cooled and the bond is secure.

Have questions about Hot Plate Welding? Contact Us for more information.

Applications

For larger or oddly shaped parts, and for softer composite materials (TPE’s, TPO’s, TPR’s) that cannot be welded by other means and when a hermitic seal of very high strength is required, hot plate welding is a must. Under-hood reservoirs and extruded seals and profiles are often hot plate welded, but the process can be applied to nearly every industry that incorporates plastics.

Precision

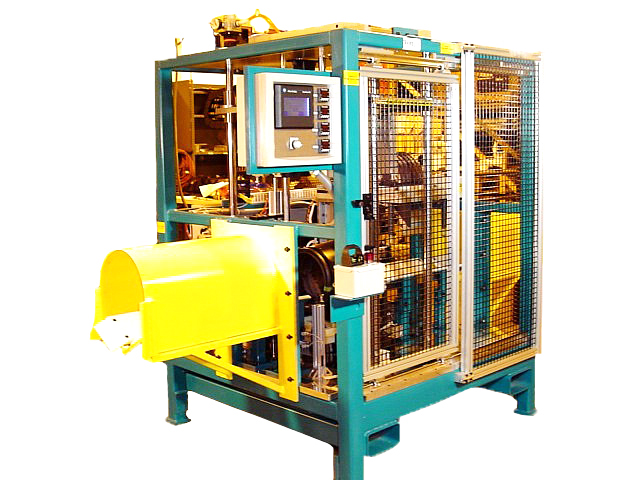

Adjustable positive stops give fine control of part relationship to the hot plate and restrict part closure to the finished dimension you wish to hold. Models with servo actuated tooling plates offer extreme precision, control of opening/closing speeds and adjustment via touch screen HMI. Digital temperature control with multi-zone feedback ensures ideal platen temperature.

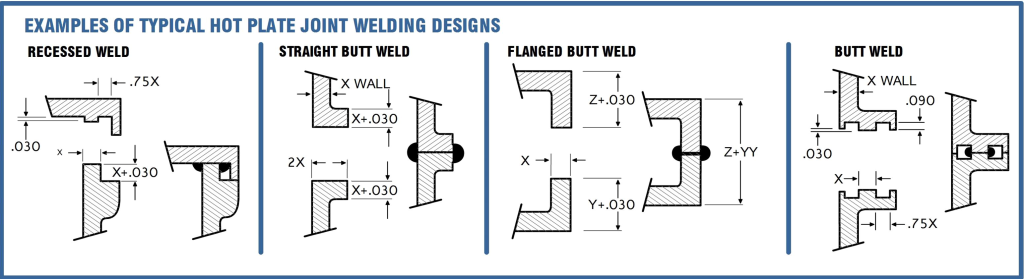

Joint Design & Tooling

Sufficient melt surface and depth is critical to high integrity welds and control of flash may also be necessary for cosmetic or functional reasons. Both can be achieved with a properly designed joint. Tooling may require a vacuum or a mechanism to secure the parts and release the finished assembly in a way that aides the operator in loading and unloading the parts.

Processing

Hot Plate Welding requires a longer cycle time and is usually reserved for applications where other, faster methods are not viable. ToolTex will assist in optimizing weld parameters and minimize machine actuation to accelerate part to part cycle time. Much like our other methods, hot plate welding is very environmentally friendly, and eliminates the need for conventional adhesives or mechanical fasteners.